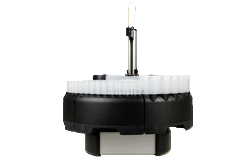

HT1000I - HT1100I: Automatic Sample Changer

HT1000I, HT1100I Automatic Spectroscopy Autosamplers - 89 Tube Capacity, 10/50ml

Spectroscopy Autosampler - ICP-OES, ICP-MS, MP-AES, Flame AAS

• Next-generation electronics • Optimised layout and short flow-path • Removable racks for continuous feeding • Different models available to meet any need

Compatible with a wide range of spectroscopy applications. It has been engineered to offer a better user experience by straight forward operations, the latest generation electronics and a rich user interface. The optimized layout allows for installation in tight spaces and you will enjoy the benefits of a short flow path.

KEY FEATURES

Straight forward process and productivity

Straight forward process and productivity

The carousel and the arm – that holds the sample probe – rotate in order to align the first sample tube to be processed. The probe is then inserted at the programmable depth; at that point, the sample is aspirated by the analyzer through the inert flow-path. As soon as this task is completed, the probe is automatically moved to the washing port where the washing pump cleans the sample probe internally and externally in order to avoid cross contamination. HT1000I is then ready to process the next sample!

Short flow-path

We typically run with a sample transfer tube 0.5 meter shorter than that of our competitors! That leads to a shorter sample rinse time, simpler/faster cleaning step and reduced bench space occupation: expect reduced argon and power supply consumption; expect longer lifetime of consumables like the tubings, the spray chamber and the torch as the contact time with the sample (matrix) is kept on a minimum level.

Optimized layout

When you look at autosamplers, the larger it is, the more expensive it is. By surveying labs in many countries, we have sized HT1000I to offer enough sample capacity to satisfy the needs of a standard lab. Oversized instruments lead to oversized costs: at the initial purchase and during operations and at maintenance – being more expensive to care about. Therefore, choosing the correct size is the best way to optimize your total cost of ownership.

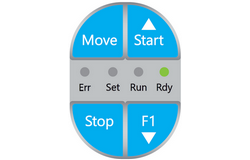

User In terface: Keypad and Software to enable a superior user experience

terface: Keypad and Software to enable a superior user experience

HT1000I offers easy setup and operation: for line priming, end-of-session washes and setup it features an integrated keypad, while for sample processing it can be controlled by the most popular ICP and Atomic Absorption software. The four integrated LEDs offer an easy visual indication of the autosampler status and PC connectivity.

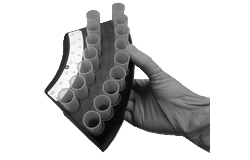

Continuous Sample Feeding

The sample carousel is organised in six racks, each of which may run a different type of sample tubes. Therefore you may designate one rack for standards and control samples using large 50ml tubes, while using smaller tubes in the other racks to maximise capacity. Racks are removable to support off-instrument sample preparation and continuous sample feeding. Furthermore, the racks are recognized so that a mismatch is not possible (e.g., putting rack #2 in the position of rack #3) to comply with the best lab practices.

Next-generation electronics: the age of smarter autosamplers is already here

Through an encoder-driven solution, HT1000I prevents the time-based drift effect you may have experienced with other systems. A powerful ARM processor runs the HT1000I, allowing support of sophisticated algorithms – such as the automated calibration procedure, the management of external stresses and automatic recovery – while minimizing the electricity consumption.

Sample carousel: designed to fit your routine

The sample carousel is organized in six racks, each of which may run a different type of sample tubes from those available. Racks are removable in order to support off-instrument sample preparation and continuous sample feeding. Furthermore, the racks are recognized so that a mismatch is not possible (e.g. putting rack #2 in the position of rack #3) to comply with the best lab practices.

COMPARE MODELS:

| Model: | HT1000I | HT1100I | HT1200I |

| Rack Number | 6 | 6 | 3 |

| Tube Capacity (up to) | 89 | 89 | 189 |

| Tube Type | 10/50ml | 10/50ml | Any |

| Closed Tubes | - | - | √ |

| Rinse Station | Included | Included | Included |

| Peristaltic Pump | - | √ | √ |

| Upgradable | to HT1100I | - | - |

TECHNICAL SPECIFICATIONS

| GENERAL FEATURES | |

| Maintenance: | Preventive counters available |

| Electrical control | USB |

| PC(1): | 2 Relays, 2 Auxiliary inputs Required for operations, installation and service |

| Required PC ports: | 1 USB (standard configuration) 2 USB and 1 RS232 (special configurations) |

| HT1000I / HT1100I SPECIFICATIONS | |

| Carousel | |

| Number of racks: | 6 (removable) |

| Rack type (open tubes): | 16 tubes - 10ml (16x100mm) 9 tubes - 50ml (30x115mm) Rack polarization |

| Featuring: |

|

| Tube capacity (Samples/ Standards) | |

| HT1001I / HT1101I / HT1103I: | 80 (10ml) + 9 (50ml) |

| HT1002I / HT1102I / HT1104I: | 54 (50ml) |

| Washing | |

| Rinse station: | Included |

| Peristaltic pump: | Included, depending on model |

| Physical features | |

| Weight: | 8kg |

| Power supply: | 100-240±10%Vac; 50-60Hz; 18W |

| Dimensions (WxHxD) (2): | 355 x 380 x 540 mm |

| HT1200I SPECIFICATIONS | |

| Carousel | |

| Number of sample racks: | 3 (removable) |

| Rack type: | check product catalogue |

| Featuring: |

|

| Tube capacity (Samples/ Standards) | |

| Open tube: | Samples: 180 (10ml) or 63 (50ml) | Standards: 9 (50ml) |

| Closed tubes | Samples: 180 (10ml) or 54 (50ml) | Standards: 3 (50ml) |

1For PC specifications refer to “HTA Autosampler Manager” flyer 2Without accounting sample probe

Operations: How it works

- Model: HT1000I-HT1100

- Manufactured by: HTA