PATROL UPLC Process Analysis System

Please contact our Sales Team for a quote.

Take control of your bottom line with real-time LC

Process development laboratories are challenged to modernize scientific processes that ensure final product quality and improve process yields. One of the critical components is process analytical technology (PAT), where timely quantitative measurements are taken throughout production to measure Critical Quality Attributes (CQA).

With Waters, in-process decisions can rely on streaming CQA feedback. The PATROL UPLC Process Analysis System provides access to real-time, chromatographic-quality analysis for in-process samples. This PAT tool gives you streaming CQA feedback, aligning UPLC technology with Quality by Design (QbD) principles in your process development laboratory.

-

Ensure final product quality and improve process yields

-

Work with real-time information that provides a great understanding of the efficiency and quality of your processes

-

Achieve best-in-class analyses designed specifically for in-process analysis

-

Rely on results that improve operational efficiency, deliver quantifiable ROI, and increase profits

Recommended Use: Designed for in-process analysis, delivering simultaneous qualitative, and quantitative information.

Take control of your process

The PATROL UPLC Process Analysis System is specifically designed for in-process analysis, delivering simultaneous qualitative and quantitative information and allowing you to dynamically adjust and control your process. Gain confidence that your process is under control and within design space with continuous system uptime and remote access from any location.

Long HPLC runtimes are no longer a hinderance to the decision-making process. Here, a 25-minute HPLC analysis was run in 2.5 minutes using UPLC.

Improve your bottom line

Rely on results that improve operational efficiency, deliver quantifiable return on investment (ROI), and increase profits with the PATROL UPLC Process Analysis System.

The system will help your lab increase process recoveries and yields, improve brand integrity with quality improvements and faster delivery, boost consumer satisfaction, and improve process understanding. With the PATROL UPLC Process Analysis System, your lab can reduce process cycle times, process and product variability, product rework, and bottlenecks.

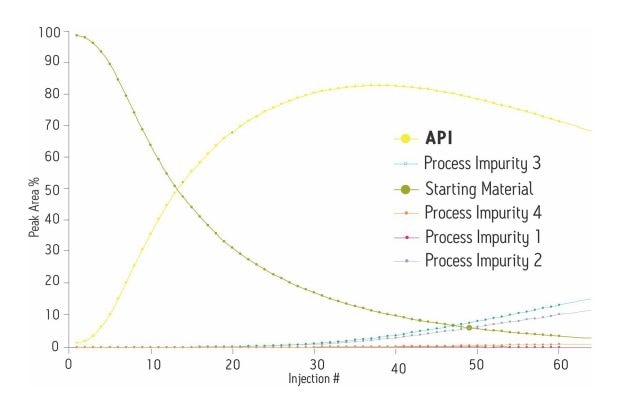

Mapping the progress of an API and its impurities in a reaction vessel with the PATROL UPLC Process Analysis System provides a better understanding of the reaction’s progress, so you can optimize product yield and purity.

Overcome process challenges with UPLC

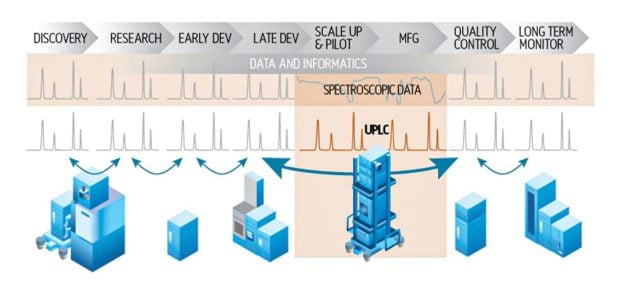

Spectroscopic technology may provide real-time identity information about processes, but it lacks the ability to simultaneously monitor multiple components at different levels, and does not provide the quantitative analysis, sensitivity, linearity/dynamic range, and resolution that ultra-performance liquid chromatography (UPLC/UHPLC) provides.

The PATROL UPLC Process Analysis System provides a fast and easy-to-use method that generates real-time data, filling the gap where the slower HPLC technique has traditionally come up short as the online and automated analytical tool desired by process chemists.

The PATROL UPLC Process Analysis System addresses a key gap in utilizing UPLC data throughout your process.

Specifications:

| Patrol UPLC Process Analysis System for Production Features | |

| Total system delay volume: | <120 μL with binary configuration, with standard 50 μL mixer or <400 μL, with standard 100 μL mixer with quaternary configuration |

| Integrated leak management: | Leak sensors as standard and safe leak handling |

| System synchronization manager: | Injection synchronization between pump and the sample enhances retention time reproducibility |

| Operating flow rate range: | 0.010 to 2.000 mL/min, in 0.001 mL increments |

| Maximum operating pressure: | 15,000 psi up to 1.0 mL/min, 9,000 psi up to 2.0 mL/min |

| pH range: | pH 2 to 10 |

| Unattended operation: | Leak sensors as standard and safe leak handling, full 96-hour diagnostic data display through console software |

| Cycle time: | <15 s inject-to-inject with binary configuration, <30 s inject-to-inject with quaternary configuration |

| Binary Solvent Manager (BSM) | |

| Number of solvents: | Up to four, in any combination of two: A1 or A2, and B1 or B2 |

| Solvent conditioning: | Vacuum degassing (six-channels): one channel per solvent, and two channels for the Process Sample Manager (PSM) diluent and sample wash solvents |

| Gradient formation: | High pressure mixing, binary gradient |

| Pump seal wash: | Equipped with a programmable active wash system to flush the rear of the high pressure seals and the plungers |

| Gradient profiles: | 11 gradient curves [including linear, step (2), concave (4), and convex (4)] |

| Primary check valves: | Intelligent Intake Valves (i2 Valve) |

| Flow accuracy: | ±1.0% at 0.500 mL/min, as per Waters AQT/SystemsQT protocol |

| Flow precision: | 0.075 %RSD or ±0.01 min SD, (0.500 to 2.000 mL/min), whichever is greater using premixed solvent |

| Compressibility compensation: | Automatic, no user intervention required |

| Priming: | Wet priming runs at a flow rate of 4 mL/min |

| Pump compositional accuracy: | ±0.5% absolute (full scale), from 5% to 95% of flow rates from 0.5 to 2.0 mL/min |

| Pump compositional precision: | 0.15 %RSD or ±0.04 min SD, whichever is greater, based on retention time |

| Primary wetted materials: | 316 stainless-steel, UHMWPE, sapphire, ruby, FEP, PTFE, ETFE, diamond-like coating, PEEK and PEEK alloys, titanium alloys |

| Quaternary Solvent Manager (QSM) And Bioquaternary Solvent Manager (BioQSM)* | |

| Number of solvents: | One to four, in any combination as standard Expanded solvent choices with optional six-port solvent select valve |

| Solvent conditioning: | Integrated vacuum degassing, four chambers Two additional for the PSM diluent and sample wash solvents |

| Gradient formation: | Low-pressure mixing, quaternary gradient |

| Gradient profiles: | 11 gradient curves [including linear, step (2), concave (4), and convex (4)] |

| Primary check valve: | Intelligent Intake Valve (i2 Valve) |

| Flow accuracy: | ±1.0% at 0.5 to 2.0 mL/min |

| Flow precision: | 0.075 %RSD or ±0.020 min SD, whichever is greater, based on six |

| Composition ripple: | <1.0 mAU (<0.1 mAU with optional 250.0 μL mixer) (baseline noise) |

| Composition accuracy: | ±0.5% absolute (full scale) from 5% to 90% from 0.5 to 2.0 mL/min |

| Composition precision: | <0.15 %RSD or ±0.04 min SD, whichever is greater, based on six replicate |

| Compressibility compensation: | Automatic, no user intervention required |

| Priming: | Wet priming can run at flow rates up to 4 mL/min |

| Pump seal wash: | Equipped with a wash system to flush the rear of the high pressure seal and the plunger |

| Flow ramping: | Range: 0.01 to 30.00 min to reach 2.0 mL/min |

| Default: | 0.45 min to reach 2.0 mL/min |

| Primary wetted materials: | 316 L stainless-steel (QSM), or Titanium (bioQSM), and/or PPS, fluoropolymer, fluorelastomer, UHMWPE blend, sapphire, ruby, zirconia, Nitronic 60, DLC, PEEK, and PEEK blend |

| Unattended operation: | Leak sensors, full 96-hour diagnostic display through console software |

| Process Sample Manager (PSM) | |

| Maximum sample capacity: | 32 available sites for process and control samples |

| Internal sample capacity: | 32 positions for standard 8 mL vials |

| External sampling: | 1 port standard |

| Number of sample injections: | Up to 60 injections per sample vial |

| Sample access: | Total random access |

| Injection mode: | Full-loop injection only |

| Injection loop volumes: | 1 μL, 2 μL, or 5 μL sample loops only |

| Dilution range: | Up to 1:100 |

| Injection precision (without dilution): | < or =0.5 %RSD for caffeine peak area, full-loop injection |

| Injection precision with dilution: | < or =1.0 %RSD for caffeine peak area, full-loop injection |

| Dilution linearity: | 1 to 50 dilution factor > or =0.999 coefficient of deviation |

| Sample carryover: | 1 to 50 dilution factor < or =0.01% of the previous injection for caffeine |

| Needle wash solvent consumption: | Variable (configured by user) |

| Sample wash solvent consumption: | Variable (configured by user) |

| Diluent solvent consumption: | Variable (configured by user) |

| Minimum injection cycle time: | Variable depending injection mode (configured by user) |

| Minimum on-line sample volume: | Variable based on injection mode, tubing ID and length required (configured by user) |

| Maximum at-line sample: | 100 μL consumed per analysis (vial) |

| Sample compartment: | 4.0 to 40.0 °C programmable in 0.1 °C increments temperature control |

| ±0.5 °C from set point measured at the control sensor temperature stability | |

| ±1.0 °C from set point measured at the control sensor temperature accuracy | |

| ±3 °C from set point as measured in air, not in a vial temperature distribution | |

| Sample compartment cooling time: | <60 minutes from 30 to 4 °C |

| Column Management (CM-A and CM-AUX) | |

| Column capacity: | CM-A: Two columns, as standard (maximum length of 150 mm with filter or guard column) or four columns (maximum length of 50 mm) can be supported with optional tubing kit, up to 4.6 mm internal diameter (I.D.) CM-Aux: Two columns (maximum length of 150 mm, with filter or guard column); one CM-Aux unit can be configured with one CM-A for support of up to four columns |

| Switching valves: | Two injector-style, nine-port, eight-position valves (CM-A only); provides programmable, automatic, random access switching, waste and bypass positions for rapid solvent changeover |

| Column compartment(s): | 4.0 to 90.0 °C, settable in 0.1 °C increments temperature range. Two independent heat/cool zones per module, up to four zones in stacked configuration with one CM-A Aux unit (see ACQUITY UPLC® H-Class and H-Class Bio System Specifications Guide for conditions) |

| Column compartment(s): | ±0.5 °C |

| Temperature accuracy: | (see ACQUITY UPLC H-Class and H-Class Bio System Specifications Guide for conditions) |

| Column compartment(s): | ±0.3 °C |

| Temperature stability: | (see ACQUITY UPLC H-Class and H-Class Bio System Specifications Guide for conditions) |

| Solvent conditioning: | Active pre-heating as standard |

| Column tracking: | eCord™ Technology column information management tracks and archives column usage history |

| Environmental Specifications | |

| Audible noise: | <65 Dba |

| Operating temperature range: | 4.0 to 35.0 °C (39.2 to 104.0 °F) |

| Operating humidity range: | 20% to 80% non condensing |

| Electrical Specifications | |

| Power requirement: | 100 to 240 VAC |

| Line frequency: | 50 to 60 Hz |

| Power consumption: | BSM 360 VAC QSM 360 VAC PSM 450 VAC CM-A 400 VAC |

| Patrol UPLC Process Analysis System Cabinet | |

| Physical dimensions cabinet: |

|

- Model: PATROL UPLC Process Analysis

- Manufactured by: Waters