SFC Prep 150 Mgm System

Please contact our Sales Team for a quote.

A greener approach to high-throughput purification

Many of today’s laboratories are looking to adopt a greener approach to high throughput purification. Designed for high-throughput, semi-prep to preparative scale purifications, the SFC Prep 150 Mgm System is made for repeat injection (bulk purification) of chiral and achiral compounds.

The SFC Prep 150 Mgm System operates at flow rates higher than traditional high-performance liquid chromatography (HPLC) systems without significant increases in back pressure – allowing for high-speed supercritical fluid chromatography (SFC) purification, improved resolution of compounds, and higher purity isolations.

Key Features:

- Achieve high-speed SFC purification and improved resolution of compounds, leading to higher purity isolations

- Reduce normal-phase solvent usage and disposal

- Benefit from increased usability with the new intuitive graphical interface of Chromscope 2.1 SFC Software supported by Windows 10

- Achieve faster equilibration, lower pressure drops across the column, solvent reduction, and lower cost per sample with Waters SFC Prep 150 Mgm

Recommended Use: For laboratories seeking to adopt a greener approach to high-throughput purification.

A greener approach to high-throughput purification

The Waters SFC Prep 150 Mgm System is perfectly suited for laboratories seeking to adopt a greener approach to high throughput purification. The SFC Prep 150 Mgm System is the ideal choice when reduction of normal-phase solvent usage and disposal is a critically important step for purification laboratories wanting to become more environmentally friendly.

SFC systems utilize liquid carbon dioxide (CO2) as its main mobile phase in combination with one or more organic solvents, resulting in faster equilibration, lower pressure drops across the column, solvent reduction, and lower cost per sample. The process is reproducible and applicable to a wide range of compounds relevant in the pharmaceutical, life sciences, chemical materials food, and environmental markets.

Achieve higher purity isolations

The SFC Prep 150 Mgm System has a maximum flow rate, CO2 and co-solvent combined, of up to 150 mL/minute allowing use of 19 mm and 30 mm columns. It also has capacity for six fraction collection positions (two liters each).

The user can take advantage of a new intuitive graphical interface controlled by the Waters ChromScope 2.1 SFC Software supported by Windows 10. The SFC Prep 150 Mgm System operates at flow rates higher than traditional HPLC systems without significant increases in back pressure, allowing for high-speed SFC purification and improved resolution of compounds, leading to higher purity isolations. ChromScope v2.1 is an updated version of ChromScope Software that enables support of the Waters SFC Prep 150 Mgm System with the ACQUITY QDa Mass Detector. Additionally, this update adds support for ELSD and the Isocratic Solvent Manager.

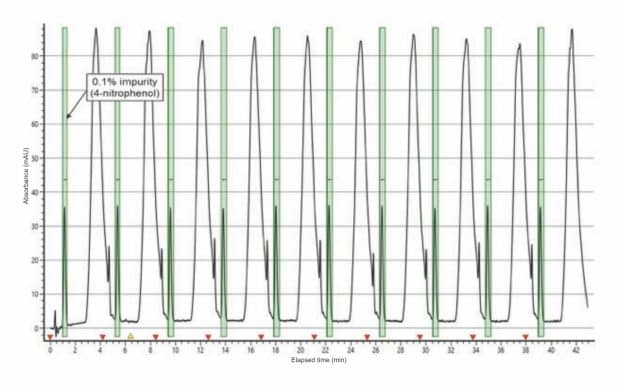

Example ChromScope v2.0 chromatogram of 10 stacked injections at 306 nm to show maximum detection of 4-nitrophenol. The peak of interest is highlighted in green with a collection time of 21 seconds.

System features that support increased throughput

The SFC Prep 150 Mgm System is designed to improve productivity with a greener approach to high-throughput purification, with features like:

- QGM Quaternary Gradient Pump: This pump delivers flowrates up to a maximum of 150 mL/min serves as the co-solvent delivery device for this system.

- P200X CO2 Pump: This high-pressure delivery pump has dual stainless-steel heads with a cam driven sapphire piston assembly; self-priming check valves; pressure sensor; pressure gauge; brushless motor, and a rupture disc assembly. The pump is designed to improve performance with feedback from the pressure sensor and mass flowmeter.

- Modifier Stream Injector: Designed to support customer requests for modified-stream injection, this device injects one sample at a time using a standard 2 mL loop and a 5 mL syringe. This allows for settable air gaps on either side of the sample, which function as a buffer between the solvent and the sample, decreasing dilution.

- Prep Collection Cabinet: This collection cabinet comes with a retractable front door allowing for easy insertion and removal of 2 liter fraction bottles. The collection cabinet has an exhaust port in the upper backside of the cabinet to easily fit laboratories around the world, and comes standard with a removable spill tray.

- Effortless integration with the ACQUITY QDa Mass Detector: The intuitive design of the ACQUITY QDa Mass Detector provides the additional data you need without the cost and complexity of traditional mass spectrometry systems and software, giving you the analytical confidence that the selectivity of mass detection brings to your analysis.

ACQUITY QDa Detector.

Specifications:

| System Features | |||

| Operating flow rate range | 20 to 150 mL/min, combined CO2 and co-solvent | ||

| Maximum operating pressure | 4350 psi (300 bar) | ||

| Recovery | >90% (within total flow rate range) | ||

| *Individual component specifications may allow operation outside the total system defined parameters. The system is designed and tested only for the ranges defined in system specifications. | |||

| P200X Pump | |||

| Ambient operating temperature | 15 to 40 °C | ||

| Ambient operating humidity | 20 to 80% RH at 40 °C (104 °F) | ||

| Pressure rating | 10,000 psi | ||

| Max operating pressure | 8700 psi | ||

| Flow range | 20 to 200 g/min | ||

| Wetted materials | 316 stainless-steel, 440C, 17–4PH stainless-steel, sapphire, GFPM, PTFE, AL | ||

| Co-Solvent Pump (QGM) | |||

| Number of solvents (Co-solvent pump only) |

Four solvents on the Solvent Select Valve (SSV) | ||

| Solvent conditioning (Co-solvent pump only) |

Sparging one channel per solvent | ||

| Operating flow rate range | 0.50 to 150.00 mL/min, in 0.01 mL/min increments | ||

| Maximum operating pressure | 6000 psi up to 100 mL/min, roll off to 5000 psi at 150 mL/min | ||

| Operating flow rate range | 0.50 to 150.00 mL/min, in 0.01 mL/min increments | ||

| Plunger seal wash | Integral, active, programmable | ||

| Delay volume | <6.5 mL | ||

| Compressibility compensation | Automatic and continuous | ||

| Priming | Self prime from solvent container on floor with dry lines | ||

| Compositional accuracy | +/-3% absolute (full scale) from 5% to 95%; and from 1 to 150 mL/min | ||

| Compositional precision | Retention time variation <0.15 min SD (uracil/caffeine; 1, 5, 20, 50, 150 mL/min; 70:30 water/methanol dial-a-mix) | ||

| Modifier Stream Injector | |||

| Default syringe | 5 mL | ||

| Default loop size | 2 mL (Optional; 5 mL, and 10 mL) | ||

| Injection volume range | 0.010 mL (10 µL) to 9.5 mL (9500 µL) | ||

| Sample delivery precision | Less than 1.0% RSD; 0.75 mL injection volume, 2.0 mL loop | ||

| Injection linearity | R2 greater than 0.995 using 20–75% of loop volume (2 mL loop) | ||

| Sample carryover | No Ketoprofen detected, therefore carry over is less than 0.01% | ||

| Primary wetted materials | 316 stainless-steel, PEEK, PTFE, borosilicate glass | ||

| Fraction Selector | |||

| Number of fractions | 1–6 fractions and 1 waste | ||

| Wetted material | 316 stainless-steel, PEEK | ||

| Gas Liquid Separator (GLS) | |||

| Total flow range | 20–150 mL/min | ||

| Co-solvent max flow rate | 75 mL/min | ||

| Operational pressure range (Optimal) |

0–100 psi 50 psi |

||

| Max pressure | 100 psi | ||

| Wetted materials | 316 stainless-steel, PEEK, borosilicate glass | ||

| ABPR-200 | |||

| Max pressure | 4400 psi | ||

| Ambient operating temperature | 15 to 40 °C | ||

| Ambient operating humidity | 20 to 80% RH at 40 °C (104 °F) | ||

| Wetted materials | 316 stainless-steel, carbon filled PEEK, platinum, Teflon™ PTFE (Polytetrafluoroethylene) | ||

| GLS Make-up Pump | |||

| Max pressure | 1600 psi | ||

| Ambient operating temperature | 4–40 °C | ||

| Flow rate range | 0.0–40.0 mL/min | ||

| Wetted materials | Synthetic ruby, sapphire, UHMWPE, PTFE, stainless-steel | ||

| Heat Exchanger | |||

| Ambient operating temperature | 15 to 40 °C | ||

| Ambient operating humidity | 20 to 80% RH at 40 °C (104 °F) | ||

| Pressure rating | 10,000 psi | ||

| Wetted materials | 316 stainless-steel | ||

| 2998 PDA Detector | |||

| Wavelength range | 190 to 800 nm | ||

| Light source | Prealigned, Intelligent Technology Deuterium D2 lamp | ||

| Wavelength accuracy | ±1.0 nm | ||

| Linearity range | <5% at 2 AU (Propylparaben 257 nm, 10 mm cell) | ||

| Optical resolution | 1.2 nm | ||

| Noise, wet | ≤60 μAU (254 nm, 2 Hz, 1 s TC, 3.6 BW res, 10 mm analytical cell) | ||

| Drift, dry | ≤5000 μAU/h (2 h warm-up, constant temp. and humidity at 230 nm, 3.6 BW res, 2 Hz) | ||

| Data rate | Up to 80 Hz | ||

| Path length | 3 mm (semi-prep flow cell) | ||

| Cell volume | 18.3 μL (semi-prep flow cell) | ||

| Pressure limit | 6000 psi | ||

| Wetted materials | 316 stainless-steel, PEEK, fused silica | ||

| Line voltage | 100 to 240 VAC | ||

| Physical Characteristics | |||

| Dimensions: D x W x H | Weight: lbs | ||

| Modifier stream injector | 14.4" x 12.4" x 11.5" | 18.0 lbs | |

| Prep fraction selector | 14.7" x 9.2" x 6.6" | 14.1 lbs | |

| Gas-liquid separator | 6.5" x 6.5" x 14.5" | 2.6 lbs | |

| ABPR | 17.5" x 6.9" x 6.0" | 16.0 lbs | |

| P200X | 24" x 14.3" x 12.3" | 84.0 lbs | |

| Heat exchanger | 20" x 4.4" x 4.6" | 12.8 lbs | |

| Instrument Control | |||

| External control | ChromScope 2.1 | ||

| External communications | Ethernet and RS-232 communications | ||

| Event input/outputs | Rear panel contact closure and/or TTL inputs/outputs | ||

| Operating system | Windows 10 | ||

| Power Requirements | |||

| Voltage range | Frequency | VA | Fuse |

| Modifier stream injector | 240 | 50 | 200 F3A/250 V |

| Prep fraction selector | 240 | 50 | 200 F3A/250 V |

| ABPR | 240 | 50 | 200 F3A/250 V |

| P200X | 240 | 50 | 200 F3A/250 V |

| Heat exchanger | 240 | 50 | 1000 F3A/250 V |

| Make-up pump | 240 | 50 | 220 F3A/250 V |

| 2998 PDA detector | 240 | 50 | 185 F3.15A/250 V |

| Julabo chiller | 240 | 50 | 425 F3.15A/250 V |

| 2545 QGM pump | 240 | 50 | 650 F6.5A/250 V |

- Model: SFC Prep 150 Mgm System

- Manufactured by: Waters